Deicing in a Retention Basin to Increase Water Availability in Mining

Thick Ice Cover and Reduced Liquid Water Storage

Canadian Pond.ca Products Ltd. was contacted to provide access to a greater amount of water in liquid form in their retention basin. As water was recycled back into the basin, it would freeze into a thick layer of ice. Every winter, extraction and mining needed to stop production because water became less available. The design of the retention basin made it particularly vulnerable to ice buildup.

How does deicing work?

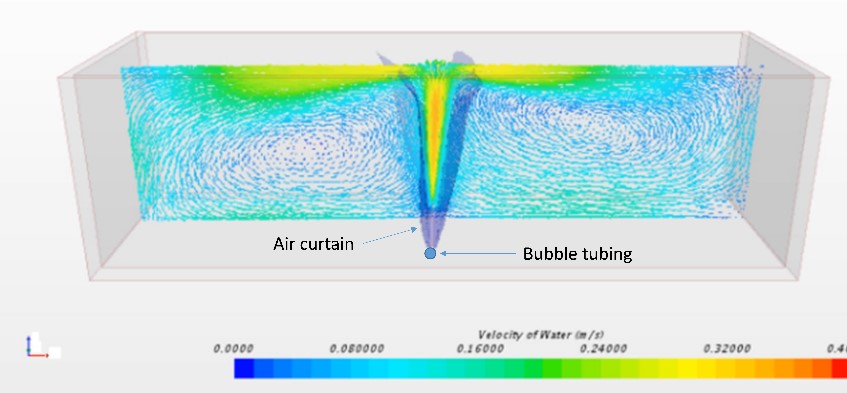

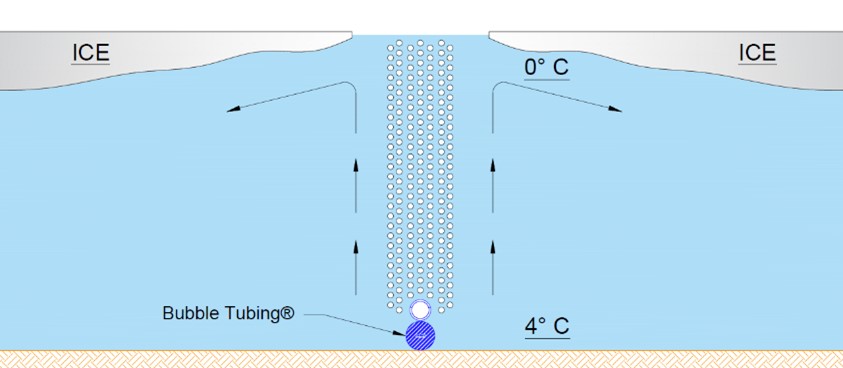

Bubble Tubing® generates an upward flux of water, bringing warmer water from the bottom of the water column to the surface, mixing the surface water with the warmer sub-layers. This warmer water melts the ice at the surface. Once the opening is created, de-icers also prevent ice formation by disturbing the surface with moving water. This principle is also known as breaking the surface tension.

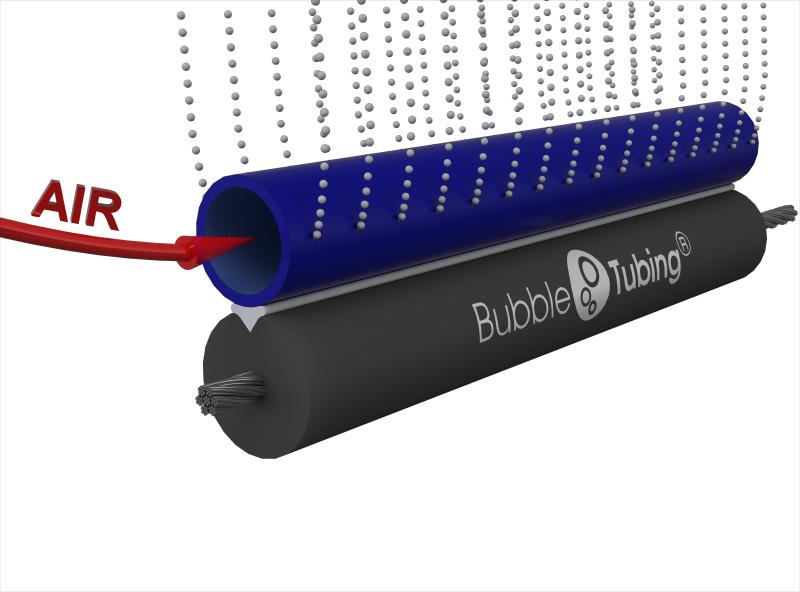

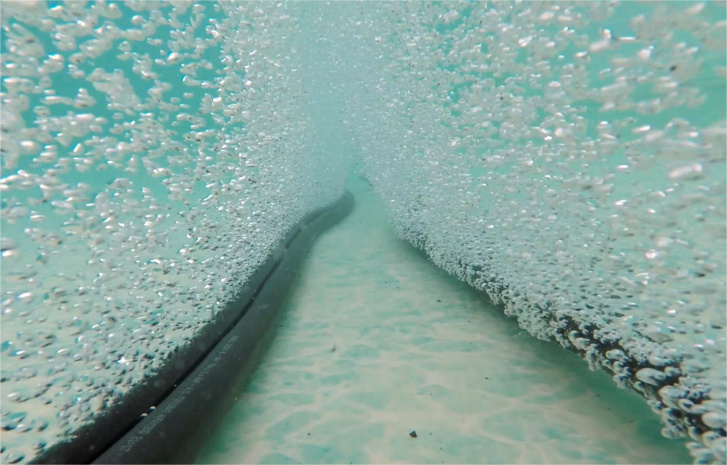

Bubble Tubing® is third party certified, industrial linear air diffuser typically used for aeration, de-icing and bubble curtains. It is designed and manufactured in Canada to our highest standards and specifications.

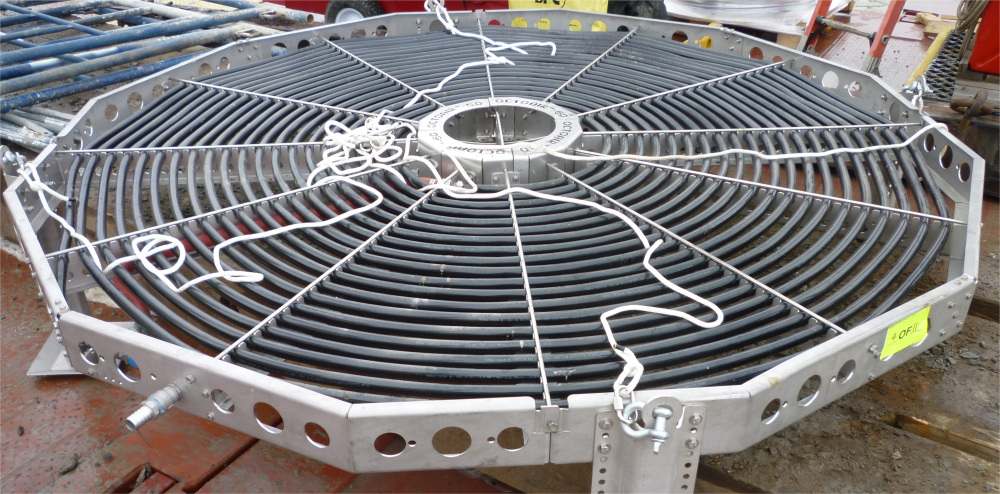

The OctoAir is an industrial grade diffuser made in Canada for aeration, oxygenation and de-icing. It is designed for industrial and municipal usage, as it is resistant to corrosion and deterioration due to pH, temperatures, water salinity, and a wide variety of chemicals. The Bubble Tubing® is bound in the spiral integrated steel support of the OctoAir.

Installation:

Twenty-two OctoAir-60s and a few lines of linear diffusers Bubble Tubing® were installed in very harsh conditions. The ambient temperature was around -20 º Celsius (-4º Fahrenheit) therefore, the basin was covered by 30 cm (12 in) of ice. Although Canadian Pond.ca Products Ltd. recommends installing decing systems before the ice forms, for security purposes and to facilitate the process, it was not possible for this project. The ice needed to be broken in order to install the diffusers in the basin, making the installation process a lot more complex. The installation was a success but required approximately two weeks longer than expected, due to weather conditions.

CanadianPond.ca Products Ltd was also consulted on the compressor sizing to ensure a consistent and effective deicing process.

The key project objective of maintaining access to liquid water during winter operations at the New Gold Rainy River Mine has been achieved. Each OctoAir-60 unit opened a radius of between 15 to 30 meters (50 – 100 ft) in the ice. There can be a yearly variation in the opening of the ice by the OctoAir’s diffusers. This variation is due to a multitude of factors such as the energy available in the water, ambient temperature and wind chill to name a few.

The key locations that were targeted, allowed for continuous operation of the mine. The deicing operation provided to the mine a greater amount of water (liquid form) in their retention basin, therefore preventing any production shut down.

Related Articles