Treatment of fracking wastewater

Hydraulic fracturing or “fracking”, consists of injecting water in the ground under very high pressures, using deep drilling, between 10 and 20 000 m3 of water to extract shale gas or oil, by fracturing the rock where it is imprisoned.

The water is added with sand which prevents the fractures from closing in, thereby recovering the gas or oil that escapes from the cracks. The water used in hydraulic fracturing is also mixed with approximately 900 to 1,000 different chemical substances, including biocides that eliminate the bacteria and molds that inhibit the escape of methane during the gas lift operations. The chemical mixtures required for this extraction operation make up between 0.5% and 1% of the liquid injected to fracture the rock.

During well operations, half of this contaminated water rises to the surface and is stored in open-air settling ponds at the drilling sites themselves and it is called Produced Water. This produced water is heavily contaminated with various pollutants including gas and liquids that have been trapped under the rock for a long time. This highly anaerobic environment is ideal for the development of sulfate-reducing bacteria, which are mainly present in this wastewater and are responsible for the development of the toxic gas H2S. It is possible to combat this anaerobic bacterial flora by aeration and by bioaugmentation of appropriate bacteria.

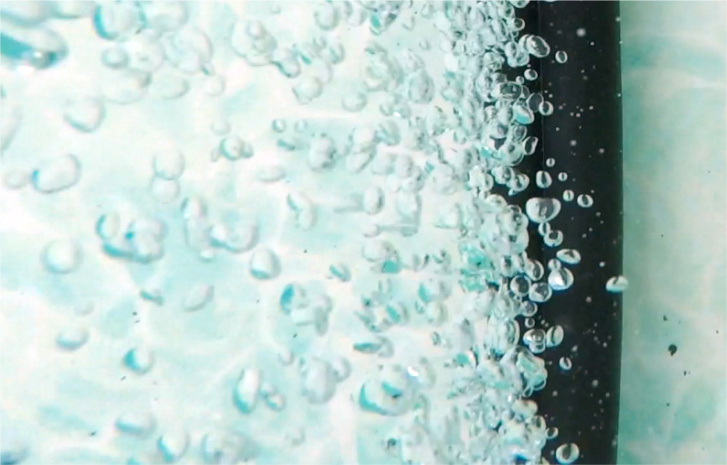

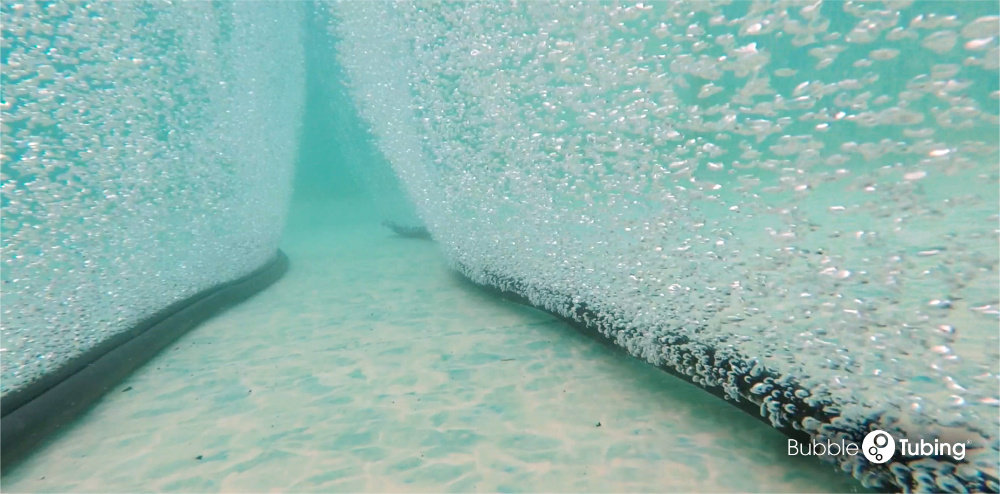

The treatment of this wastewater is important and necessary in order to reuse some of this treated water in another fracking process. The goal is to use as little as possible of fresh water in fracking. The treatment is generally done in 2 steps. First, one or more aeration systems must be installed in each basin. An aeration system usually consists of a compressor capable of supplying 8 lines of air. These 8 lines of weighted tubing, which we call Torpedo, deliver air from the compressor to strategically placed diffusers in the pond. 2 choices of diffusers are available using Bubble Tubing® technology:

- The OctoAir-10 (8 units per system) is a disc-shaped diffuser that allows a concentrated release of fine bubbles at a particular location for effective and intense decontamination.

- Linear Diffuser Bubble Tubing® (100′ (30 m) per system) allows aeration over a larger area with the same amount of tubing as the OctoAir-10 which is concentrated on a more targeted area.

This aeration allows the H2S already formed to degas and to promote an aerobic bacterial flora which competes with the anaerobic bacterial flora present in the wastewater to be treated.

Afterwards, specific bacteria can be added to the wastewater basins. These bacteria will accelerate the treatment of the wastewater and avoid the strong odors (rotten eggs) and the dangers (toxicity, corrosivity, and other risks) associated with hydrogen sulfide produced in these anaerobic water ponds. Bacterius® PRO-H2S has been specially developed to treat these highly contaminated wastewaters. Bacterius® PRO-H2S acts in two steps for the treatment. A first strain of bacteria within the Bacterius® PRO-H2S helps to reduce organic matter in an anaerobic environment. Once there is sufficient oxygen in the water, thanks to the operation of the diffusers (OctoAir-10 or Bubble Tubing®), a second strain of bacteria present in the Bacterius® PRO-H2S begins its bacterial growth by gradually taking over the anaerobic bacteria until there is a predominance of aerobic bacteria introduced by the Bacterius® PRO-H2S in the wastewater pond.

Aeration and bioaugmentation solutions, combined, increase your chances of success and speed of treatment! Our Bubble Tubing® products offer one of the best oxygen transfer rates observed on the market for an effective treatment of the water body thereby reducing the risk of H2S presence.